Feed Extruder

Henan Huatai Intelligent Equipment Group provides the latest technology for the production of puffed products, which is suitable for the aquatic feed and pet food industries that have strict requirements on products.

Introduction of feed extruder:

The feed extruder is a single-screw extrusion extruding equipment, which is mainly used to produce various types of commercial poultry, aquatic products and pet extruded food and feed. It can be used as a single raw material or as a pretreatment of raw materials in the production of vegetable oils and fats. The feed extruder is suitable for raising fish, shrimp, frogs, pigs, ducks, etc. It has the advantages of soft and puffing, high protein, complete nutrients, floating on the water surface for a long time, without wasting feed, and adding trace elements to promote the rapid growth of fish.

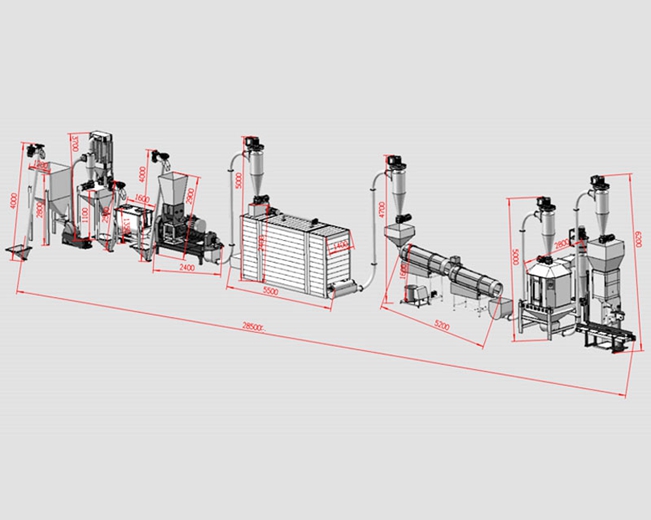

Main process and equipment

Features of feed extruder:

1. The model design is novel, the structure is compact, and the production efficiency is high.

2. Reliable work, sturdy and durable, low failure rate, convenient operation and maintenance.

3. Simple and convenient to use, stable transmission and low noise.

4. The main components are made of special alloy materials through heat treatment, with long service life.

5. The screw design has a strong self-cleaning function, and the screw groove can be cleaned by itself, so when changing the formula and product variety, there is no need to stop the cleaning. The screw has a strong pumping effect, and the material sticks and diffuses. Fast, product quality is relatively stable.

6. The screw discharge nozzle adopts modular design, which is easy to adjust and cheap.

7. It can be equipped with an automatic feeding system. The feeder is a horizontal conveying screw controlled by the latest switched reluctance speed regulating motor in the world, and the other end is connected to the extruder. The extruding output can be controlled by adjusting the amount of feed. (Quantitative feeding, and can effectively prevent the material from arching).

8. Cutting system, independent cutting device is easy and fast to connect with the body, variable speed cutting head, can easily adjust the cutting knife, and can easily adjust the gap between the cutting knife and the template. The required material diameter and length can produce products of different specifications and material shapes.

9. No adhesive is needed to process the floating feed, and it can maintain stability in water for more than 2 hours.

10. It can process round products of ¢1-20mm (templates can be customized as needed).

11. The main shaft is a combined structure, and the spare extension shaft can adapt to the puffing processing of different raw materials.

12. The small and medium equipment is especially suitable for scientific research institutions, special breeding farms or medium and small feed factories.

13. Dry and wet dual-use, in the single-screw extruding equipment above 30KW, a conditioner can be added for wet expansion, and both have the ability of dry and wet dual-use.

Huatai advantage

Flawless Project Delivery is the core of Huatai’s Project Delivery Management System – the platformization of our contract delivery security system. Man from Huatai, customers, suppliers and partners; equipment for work; raw materials and supplies; local and global know-how, experience and best practices; principles, standards and requirements, as well as other elements related to the delivery of our products, plants, solutions and services are included in this system. These elements are well organized into standard operation processes with scientific, optimized algorithm to tell what to do, when to do it, how to do it and how to manage the potential risks to ensure fast, quality and satisfied execution with high efficiency and reduced costs. With Huatai Project Delivery Management System, anyone whoever from Huatai or our local partnering engineering and service teams can deliver high quality work with best executions.